Page 64 of 408

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 12:14 pm

by StudioShutIn

what I'd really like to see is more info on that Noise generator that Cloudscapes made and that Squarewave Shaper/PLL that LaoWiz put together

c'mon guys! we need info!

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 2:41 pm

by Jero

Laowiz made a pll?!

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 3:42 pm

by phantasmagorovich

PLL is not Schumann PLL. A Phase Locked Loop is - as far as I know without knowing zilch about DIYing - something not very uncommon. Well, it is, because until very recently only Schumann made good use of it but the basic idea is in some DIY bible. (25 easy circuits from the 1950's or something)

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 3:58 pm

by ARC Effects

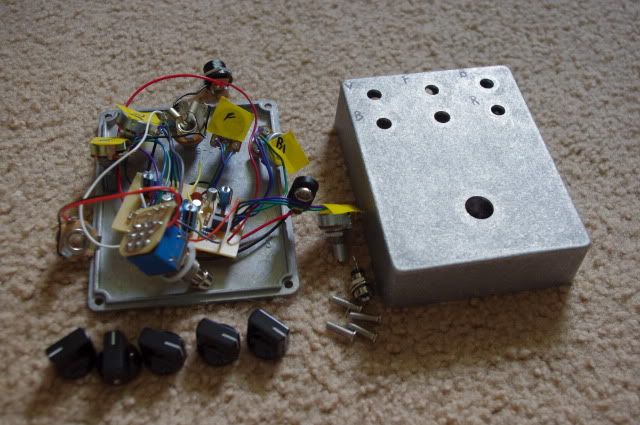

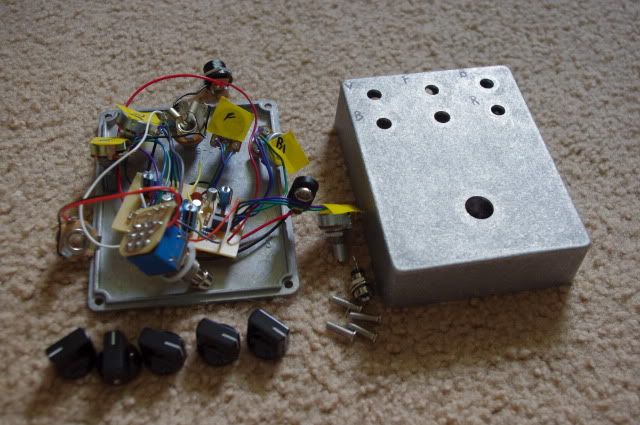

Also, here's something new.

I got this pedal (lunar module deluxe clone) in trade and it had no finish and a few off center holes. Since it would be easy enough for me to fix I went to town.

Before :

After a fresh powdercoat finish and fixing the drill holes :

The internal wiring isn't as clean as I'd like (but you've seen my OCD builds

) it but it works and nothing looks like it would ever be faulty so I just left that be for the most part (went over a few of the jack joints, shortened a few pot wires, and ditched the battery snap)

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 4:16 pm

by LaoWiz

eatyourguitar wrote:I just checked that thread and I never saw the fixx fuzz before today, I was actually thinking of the fulltone 69 that had a knob called "bias". not really biasing a collector so I dunno why he calls it bias. all it is is a 25k pot with two lugs used. so it isnt in the circuit when fully ccw. the original fuzz face doesnt like low impedance signals. like after a boost. so if your pickups are anywhere from 5k to 25k at the output jack of the guitar and the booster has a low output impedance like 1k, the 25k pot lets you trick the fuzz face into thinking its a guitar. like my phantom octave passes a mostly clean signal on keyboards. I actually went and bought a impedance transformer. the quick and easy way is the 25k pot like andy fuller. other people have built the LPB>25K>Fuzz Face in one box. so when you kick on the LPB it kicks in the 25k pot.

in your situation, its the opposite, you have too much fuzz. I would say fuck it, gots a new fuzz pedal.

Oh, I must have been reading another post about FUZZ that you were a part of... My boost into the Fuzzrite is too much or too little. There's a sweet spot somewhere in there, though. Sounds pretty fucking good from menacing to a good rocking ass overdrive with the guitar vol rolled back. Did you do the pickup simulator circuit from AMZ? I need to build one of those handy utility boxes... I'll try a smaller pot value and some other things and post that one soon after I etch the box...

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 4:26 pm

by LaoWiz

StudioShutIn wrote:what I'd really like to see is more info on that Noise generator that Cloudscapes made and that Squarewave Shaper/PLL that LaoWiz put together

c'mon guys! we need info!

The one I made is just a simple fuzz that goes into a 4046 phase locked loop chip. The 4046 part started from a circuit that is in the Hardware Hacking Nicholas Collins book. He basically just gives you a rough idea of how the chip works and gives you a starting point. In the end, the circuit I made was a little different. I had it on the breadboard for a couple of months and got sick of fucking with it so I decided to put it to rest. In the end, a square wave fuzz that goes into an a chip that's trying to lock onto your signal but is getting confused as fuck so you get an oscillating noisy wah effect that goes all over the place. Was going for that guitar freakout in Grinderman'n Grinderman's, No Pussy Blues. Not as crazy but I'll revisit that circuit sometime down the road...

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 4:40 pm

by Dandolin

"That I must above all things love myself."

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 4:51 pm

by Dandolin

LaoWiz wrote:TIm Escobedo Square Wave Shaper going into a phase locked loop chip.

[Repetition of large pictures of biutiful box eschewed]

Another huzzah for this--thanks for the additional deets on the circuit. Would love to hear more on the finish--how were the cool surrounds to the face-side knobs applied--stencil? stamp? And how did you go about "industrializing" the finish? And what do all the controls do (I assume those are additional knobs topside)? Just very creative work--on so many counts I like the creativity on display in this thread so much more than 99% of the commercial product out there, and yours certainly are among the tops I've seen. It (and some selected other work here) is playing a major role in pushing me to rolling my own stompology. So, consistent with your available time and patience, I'd be grateful for any deets/insight as I survey what's possible under my own steam--a little goes a long way. Thanks for sharing--the inspirationz are valued here on my little pharm....

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 4:58 pm

by Dandolin

StupidDream88 wrote:After a fresh powdercoat finish and fixing the drill holes :

Schweet! Stupid noob question--did you powdercoat this yourself, or send it out? I mean this ain't your standard garage-applied kind finish right? Or are there schweet powdercoating kits in the clearance at the local Ace Hardware that I'm always meaning to check out?

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 5:00 pm

by theavondon

TRIP-TRIP-TRIP-TRIP-TRIPLE POST

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 5:58 pm

by Dandolin

Hat trick!

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 9:15 pm

by LaoWiz

Dandolin wrote:LaoWiz wrote:TIm Escobedo Square Wave Shaper going into a phase locked loop chip.

[Repetition of large pictures of biutiful box eschewed]

Another huzzah for this--thanks for the additional deets on the circuit. Would love to hear more on the finish--how were the cool surrounds to the face-side knobs applied--stencil? stamp? And how did you go about "industrializing" the finish? And what do all the controls do (I assume those are additional knobs topside)? Just very creative work--on so many counts I like the creativity on display in this thread so much more than 99% of the commercial product out there, and yours certainly are among the tops I've seen. It (and some selected other work here) is playing a major role in pushing me to rolling my own stompology. So, consistent with your available time and patience, I'd be grateful for any deets/insight as I survey what's possible under my own steam--a little goes a long way. Thanks for sharing--the inspirationz are valued here on my little pharm....

Thanks for the kind words! I'm didn't get a second of sleep last night so hopefully this will make sense...

There's two volume controls, two controls for the square wave shaper, and two controls for the part that tune the oscillator part of the phase locked loop. It's really something I was just experimenting with and it got to the point where it was as good as it

was going to get and I said fuck it. Probably won't use it much but it could be useful at some point. I'll try to record some video of it.

I pretty much always etch the boxes I make. The trick to get a raw look is a million times easier than getting a good super clean etch. At least for me. I always buy ferric chloride (the acid) from radio shack but should probably buy it in powder for to create the best strength mix for etching aluminum. If you have never etched, there's a little bit of trial and error and some folks get some really immaculate detailed designs burned in. In all of my attempts the acid has always eaten into areas I didn't want it to but its probably because I like to etch deep and would leave the acid on for too long. The acid heats up with because of its reaction to the metal and you don't want it to get too hot. I place the box in a plastic container with the box face up and apply the acid with a little rubber blower bulb. I let it burn in for awhile and then dunk the box into another container full of water to let it cool down and then I check to see how deep it is.

With this particular box, I wanted to do it fast. I made sure the dials were burned in and didn't care to much for the border. Once I was done, I scrubbed the gunk out with a stiff brush and then applied some spray paint. Let that dry and then care fully wetsanded with a fine grit to take the toner off of the non etched parts (the control dials, border) and continued sanding to take off some of the paint to ruff it up a bit. I usually clearcoat with this stuff thats made for aluminum auto hub caps but didn't do it for this one. Make sense?

The dials were done with this lovely program:

http://stiftsbogtrykkeriet.dk/~mcs/Scale.htmlTry these values for a starting point on the very first one: 50,40,20

Then I import into photoshop and that's it. If you have more questions PM me. Etching is fun. I think I like it better now when it's not perfect and rawer looking. At the very least, it's easier than trying to get the super clean fine detailed etches that some of the etch masters have achieved. PM me if you have any detailed questions. I may try to do an etching demo video for fun. Anyways, PM me if you have any particular questions. Beware though, once you get the bug you won't want to do anything else!

Cheers

Richard

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 10:21 pm

by ARC Effects

Dandolin wrote:StupidDream88 wrote:After a fresh powdercoat finish and fixing the drill holes :

Schweet! Stupid noob question--did you powdercoat this yourself, or send it out? I mean this ain't your standard garage-applied kind finish right? Or are there schweet powdercoating kits in the clearance at the local Ace Hardware that I'm always meaning to check out?

I did it myself using a Craftsman Powdercoating Gun and a toaster oven

Very easy to do yourself if you have the right stuff

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 10:34 pm

by Dandolin

Awesome--thanks!

Re: Let's see your finished DIY projects!

Posted: Mon Jun 13, 2011 10:39 pm

by Dandolin

lao Wiz/Richard--thanks so much for the info--this is gonna be a great primer for trying some etching myself! I tend to like the rougher etched look myself--kinda seems to fit the character of the circuits I like and of aluminum itself. Thanks again! ILF forever!

c'mon guys! we need info!

c'mon guys! we need info!

c'mon guys! we need info!

c'mon guys! we need info!

) it but it works and nothing looks like it would ever be faulty so I just left that be for the most part (went over a few of the jack joints, shortened a few pot wires, and ditched the battery snap)

) it but it works and nothing looks like it would ever be faulty so I just left that be for the most part (went over a few of the jack joints, shortened a few pot wires, and ditched the battery snap)